JOEST fluidized bed sand coolers (DWFA) are used to cool hot recovered sand.

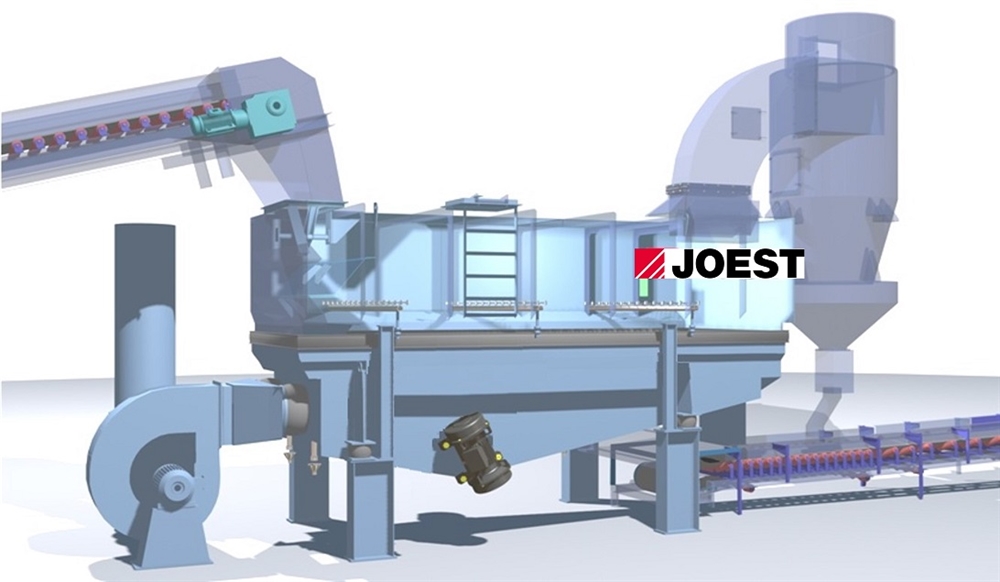

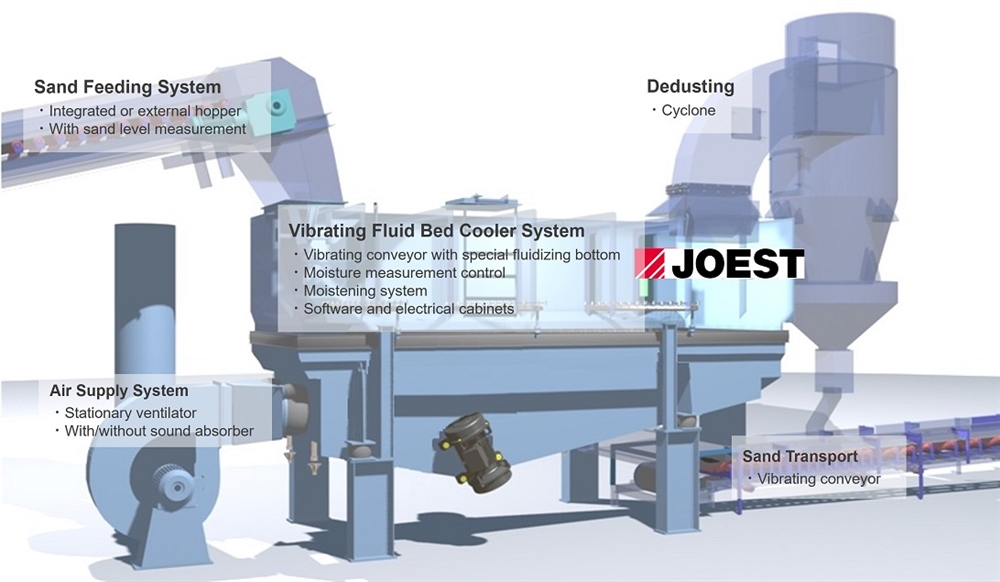

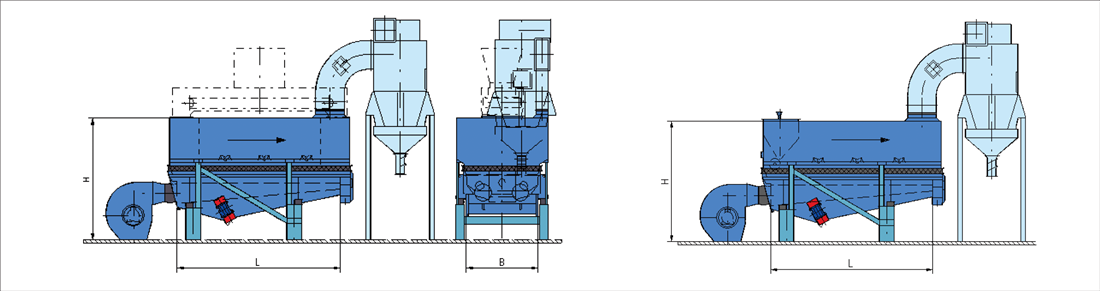

It consists of a vented vibrating conveyor, a fixed exhaust hood, a water injection unit, an air fan, and a control cabinet.

The recovered sand is effectively cooled by utilizing the vaporization heat generated when water is added and evaporated in the fluidized bed.

The amount of water added is precisely controlled according to the temperature and throughput to adjust the moisture content of the recovered sand after cooling.

Major Processes

Low power consumption

No mixing tools (reduced mechanical energy consumption)

No high-pressure blowers (reduced airflow due to lower equipment height)

Clean cooling process with no mixing of evaporative latent heat during cooling

Low vibration transmission

Sand transport by fluidized bed

Low amplitude (2 - 4 mm)

Low air vibration

Large hood and horizontal fluidized bed

Low frequency

Adjustable frequency

- Stable final sand moisture adjustable to 1.6 - 2.2% ±0.4%, regardless of return sand inlet moisture

- Good and homogeneous final sand quality due to fluidization and continuous cooler operation

- High cooling effect and energy saving with compact design

- Automatic sand feed control

- Continuous operation with throughput adjustment regardless of sand feed volume fluctuations (40% to 100% of the processing capacity)

- Machine supply for easy installation in existing plants

- Machine with integrated feed hopper for easy installation in existing plants (option)

- Process control by PLC with LCD monitor and error analysis of all major equipment functions

- Few consumable parts, less maintenance

- Equipped with sand homogenizer in the cooler inlet

JOEST sand cooler consists of water supply & water control unit, pre-mixing device, moisture measurement, dust & emission control display, and sand supply control.

Water supply & water control unit

Water quality control and stable supply can be achieved by controlling water spraying through a filter for the purpose of homogeneous and stable water supply.

Pre-mixing device

A polygonal screen is installed in front of the sand cooler for pre-mixing and homogenization at the sand cooler inlet. This reduces the inflow of sand lumps and ensures optimal heat transfer and flowability by homogenizing the sand layer on the fluidized bed in the sand cooler.

Moisture measurement

For the purpose of controlling final moisture content, moisture content is measured by moisture sensors installed at the sand cooler outlet (left and right), and moisture content is controlled by PLC-PID control based on the measurement results.

Dust & emission control display

To reduce dust and sand emission, the air velocity above the fluidized bed is lowered and dust seals are installed between the fixed covers. In addition, dust and fines are separated by a cyclone, and dust discharged from the cooler is returned to the line to reduce the amount of dust and sand emission during sand cooler operation.

JOEST fluidized-bed sand cooler DWFA series

| Performance in t/h with Cooling | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | W | x | L | Motor Type |

120℃ -40℃ |

100℃ -40℃ |

80℃ -40℃ |

Water Consumption Max (liter/h) |

Supply Air (Nm3/h) |

Exhaust Air (Bm3/h) |

Cyclone Type (Option) |

| DWFA | 1750 | x | 4000 | JV 178 | 55 | 63 | 76 | 2300 | 12250 | 16100 | Z 1300 |

| DWFA | 1750 | x | 4400 | JV 178 | 60 | 69 | 84 | 2500 | 13500 | 17700 | Z 1300 |

| DWFA | 2100 | x | 4000 | JV 208 | 66 | 76 | 91 | 2750 | 14700 | 19300 | Z 1450 |

| DWFA | 2100 | x | 4800 | JV 208 | 79 | 91 | 108 | 3300 | 17600 | 23100 | Z 1550 |

| DWFA | 2100 | x | 5600 | JV 208 | 92 | 107 | 125 | 3600 | 20600 | 27000 | Z 1650 |

| DWFA | 2500 | x | 5600 | JV 248 | 110 | 126 | 148 | 4650 | 24500 | 32100 | Z 1850 |

| DWFA | 2500 | x | 6400 | JV 248 | 125 | 145 | 169 | 5300 | 24900 | 36600 | Z 2050 |

| DWFA | 2500 | x | 7200 | JV 278 | 142 | 163 | 190 | 6000 | 31600 | 41400 | Z 2050 |

| DWFA | 2500 | x | 8000 | JR 408 | 157 | 182 | 215 | 6650 | 35100 | 46000 | Z 2300 |

| DWFA | 2500 | x | 8000 | JR 608 | 173 | 199 | 230 | 7300 | 38500 | 50500 | Z 2300 |

| DWFA | 2500 | x | 9600 | 2 x JR 608 | 197 | 229 | 260 | 8350 | 44500 | 58000 | Z 3000 |

| DWFA | 2500 | x | 11200 | 2 x JR 608 | 230 | 267 | 303 | 9750 | 52000 | 65600 | Z 3000 |

| DWFA | 2500 | x | 12800 | 2 x JR 608 | 262 | 305 | 346 | 11100 | 59599 | 77500 | Z 3000 |

* Performance data of cooler are valid at a dew-point temperature of the supply air of max. 18 degrees C.

Green Sand

เทคโนโลยีของไอริค

เรานำเสนอการประมวลผลวัตถุดิบเหมาะสมยิ่งขึ้นโดยการผสมผสานความเชี่ยวชาญที่สะสมมาของกลุ่มไอริคทั่วโลกเข้ากับความพยายามพัฒนาด้านเทคโนโลยีของเรา