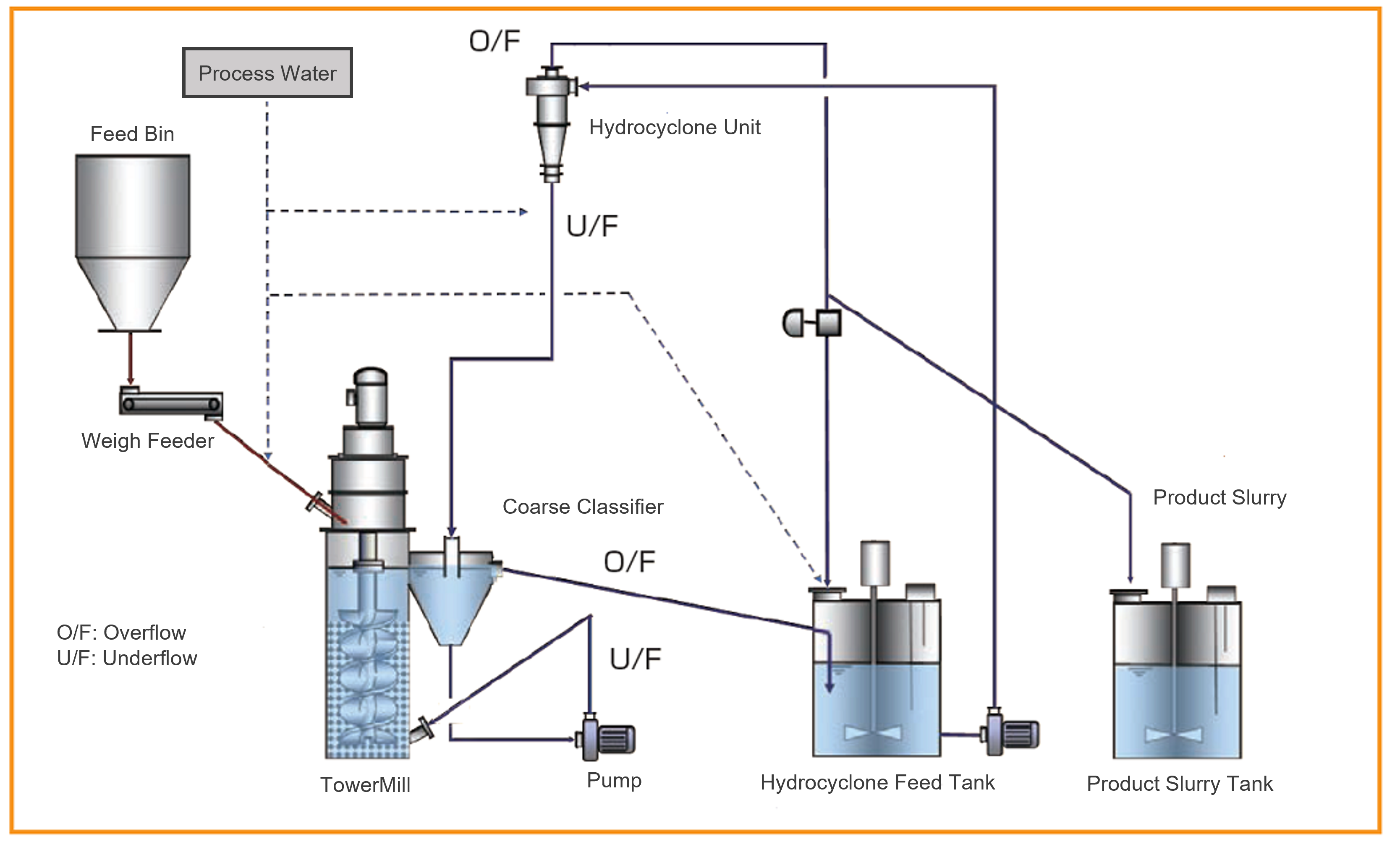

TowerMill is a vertical agitated media mill developed in Japan in the 1950s. Until now, TowerMills have been used in ferrous and non-ferrous mines for processes of ore grinding, flue gas desulfurization (FGD), limestone grinding for neutralization and further in other industries such as environmental fields all over the world, for the advantageous capability of high capacity and fine grinding. In particular, TowerMills are adopted for replacing conventional horizontal ball mills or for fine grinding after coarse grinding by ball mills.

Major processes

- Feed size: max. 40mm

- Product size: from microns down to sub-microns

- Standard mill size range from 0.4kW up to 1120kW

- Energy saving due to highly effective grinding

- Space saving and suitable for retrofitting

- Low noise level and small vibration

- Continuous and high capacity grinding

- Maitenance-free mill body due to its unique shell grid liner mechanism (material lining)

- Simple grinding mechanism, solid structure

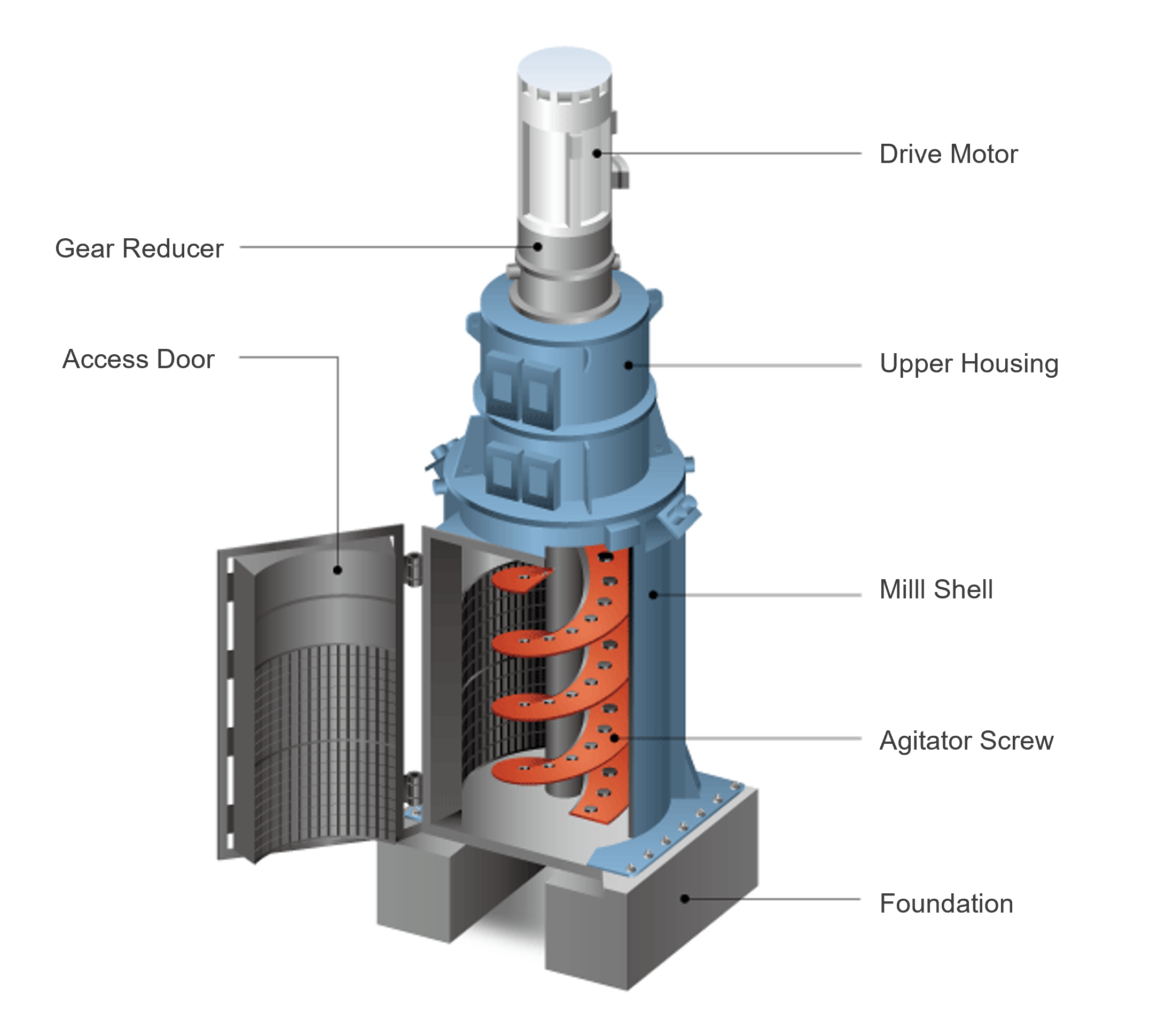

EIRICH TowerMill effectively agitates the grinding media filled in mill shell with screw

equipped

with double helical flights. By the impact and abrasion effect the material is ground in mill

shell.

Mill screw with double helical flights is hung in the cylindrical shell (Mill shell

assembly) and it is rotated by the driving device (Main drive motor) installed at the

top

of TowerMill via the reduction mechanical device (Gear Reducer).

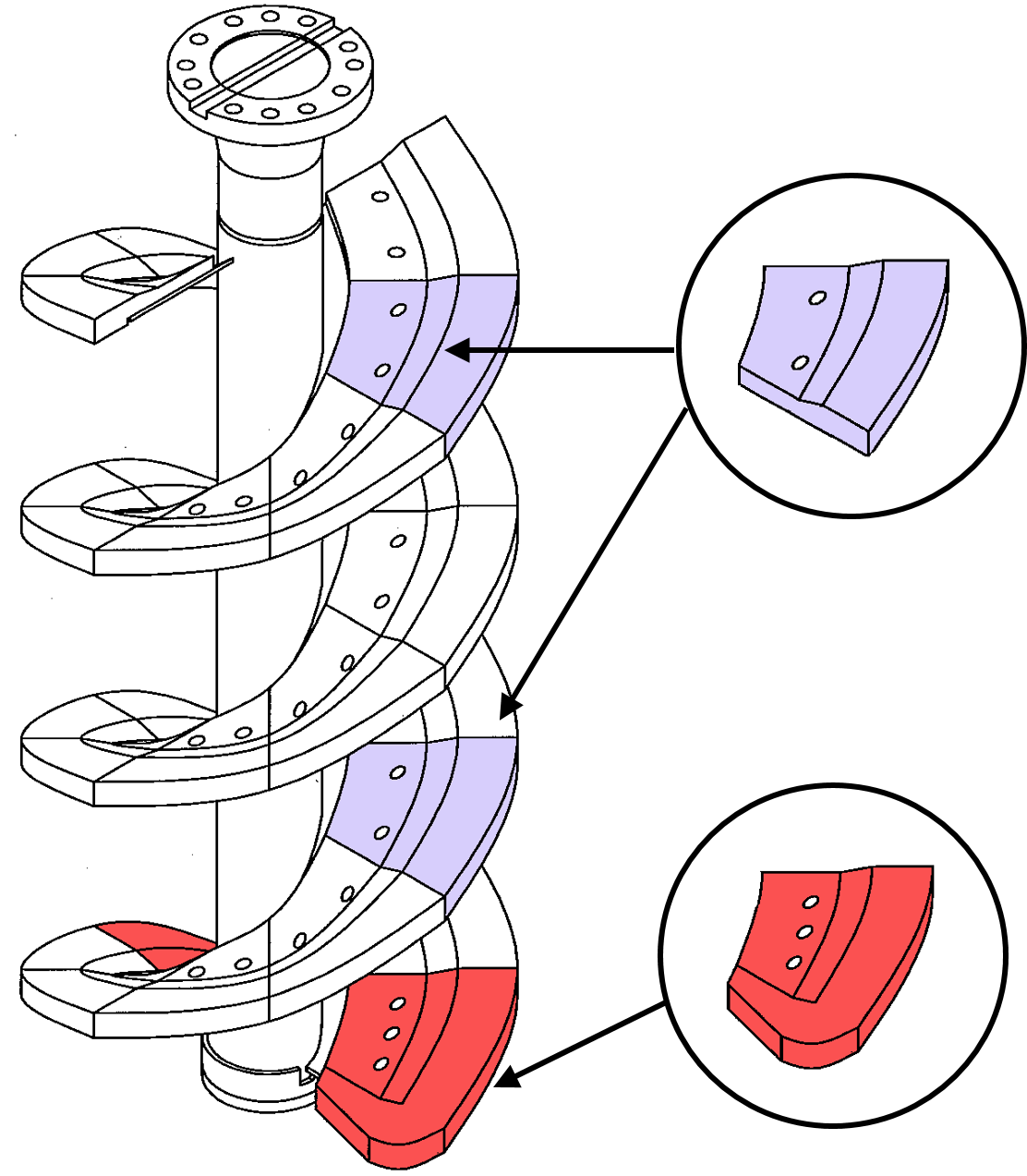

TowerMill grinds the material in the slurry by impact/abrasion motion of grinding media. Mill

body

is made of normal steel and the internal surface is rubber lined for corrosion-resistance. For

abrasion resistance, screw double helical flights are equipped with replaceable liners and mill

body internal surface is equipped with shell grid liners that enables to form a layer of

material

(grinding media and grinding material) lining.

- Iron ore

- Copper ore

- Gold ore

- Zinc/Lead ore

- Nickel ore

- Limestone

- Quicklime

- Limeslake

- FGD slurry

- Coke-oil

- Magnesium hydroxide

- Fly and bottom ash

- Others

EIRICH TowerMill®

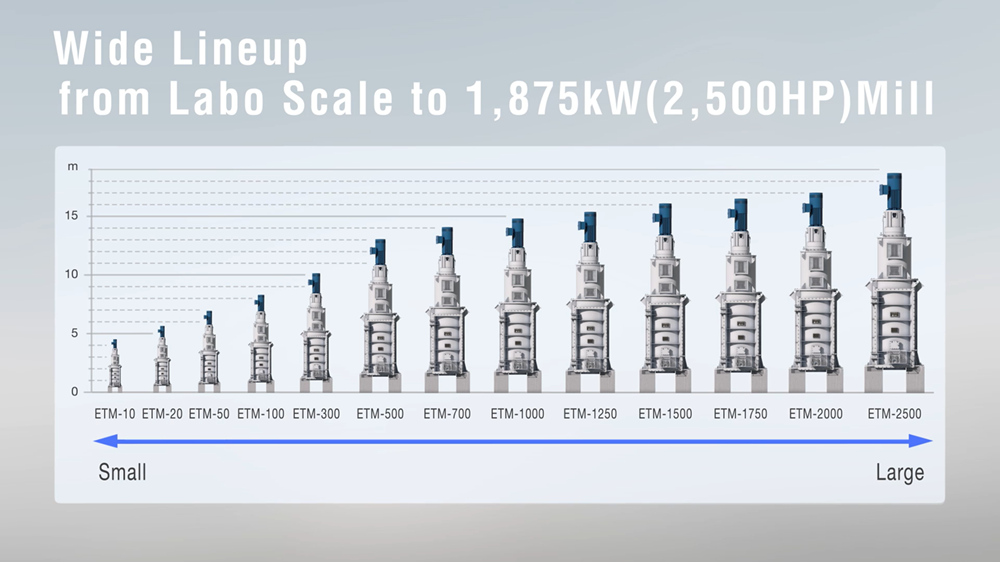

| Type | Power(kW) | Height(m) | Mill Diameter(m) | Remarks |

|---|---|---|---|---|

| NE-008 | 0.4 | 1.6 | 0.14 | for test |

| NE-024 | 7.5 | 1.6 | 0.6 | |

| NE-024L | 3.7 | 1.2 | 0.6 | |

| ETM-10 | 15 | 4.4 | 0.6 | Small |

| ETM-20 | 22 | 5.6 | 0.7 |  |

| ETM-50 | 55 | 6.9 | 1 | |

| ETM-100 | 110 | 7.4 | 1.2 | |

| ETM-150 | 135 | 7.7 | 1.4 | |

| ETM-300 | 280 | 10.8 | 1.8 | |

| ETM-500 | 370 | 11.5 | 2.4 | |

| ETM-700 | 520 | 12.4 | 2.7 | |

| ETM-1000 | 750 | 13.1 | 3.3 | |

| ETM-1250 | 1000 | 13.6 | 3.3 | |

| ETM-1500 | 1120 | 14.2 | 3.3 | |

| ETM-1750 | 1300 | 14.6 | 3.3 | |

| ETM-2000 | 1500 | 15.1 | 3.3 | Large |

| ETM-2500 | 1875 | 16.0 | 3.3 | Large |

Industrial Chemicals

Building Materials

Environmental Protection

Ceramics

Glass

Chemical Products

Paint/Ink/Coating

Metallurgy

Link to Reference Projects

(pdf, 2.0 MB)

EIRICH TowerMill

เทคโนโลยีของไอริค

เรานำเสนอการประมวลผลวัตถุดิบเหมาะสมยิ่งขึ้นโดยการผสมผสานความเชี่ยวชาญที่สะสมมาของกลุ่มไอริคทั่วโลกเข้ากับความพยายามพัฒนาด้านเทคโนโลยีของเรา