Market & application

Suited for such customers who are:

- Considering measures to prevent sudden breakdowns

- Considering streamlining maintenance activities

- Interested in reducing the time and cost of engineer dispatch

- Concerned about maintenance management and parameter management because many years have passed since the facilities were installed

Applications for:

- Predictive maintenance of Eirich mixer and various ancillary equipment

- Identifying and solving the cause of trouble at an early stage if occurs

- Software modification and touch panel modification

- Data analysis and improvement to optimal parameters

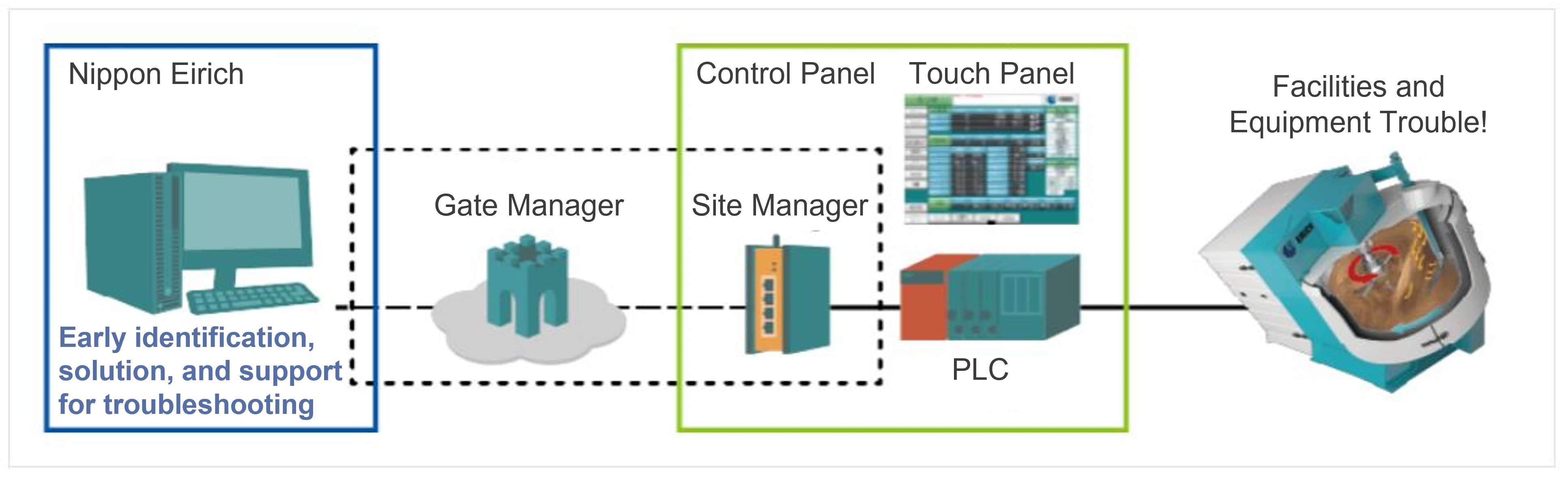

Early and emergency

- Early identification, solution, and support for troubleshooting

- When trouble occurs, we connect to the PLC remotely and check it to identify the cause of the machine stoppage or other trouble as early as possible.

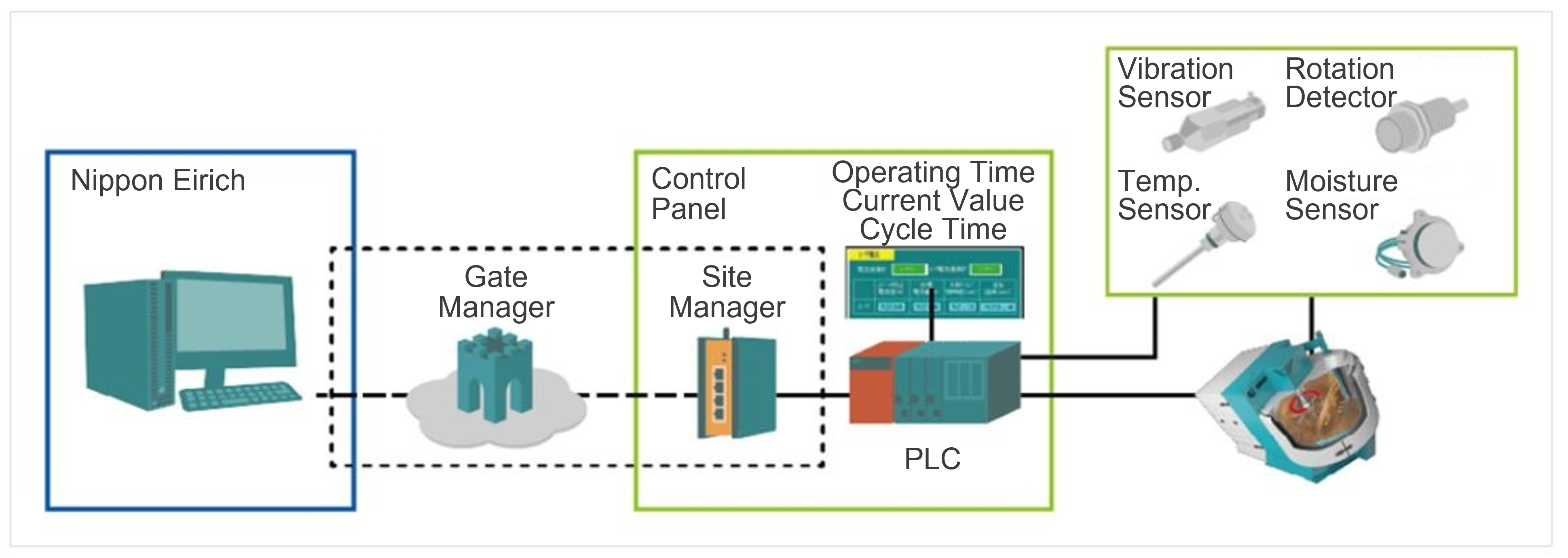

Communication

- Various services using the latest communication technology

- Check the total operating time, rotor motor current, cycle time, and vibration data of equipment and notify the timing of inspection*2

- *2

In some cases, each measurement unit is required for data collection.

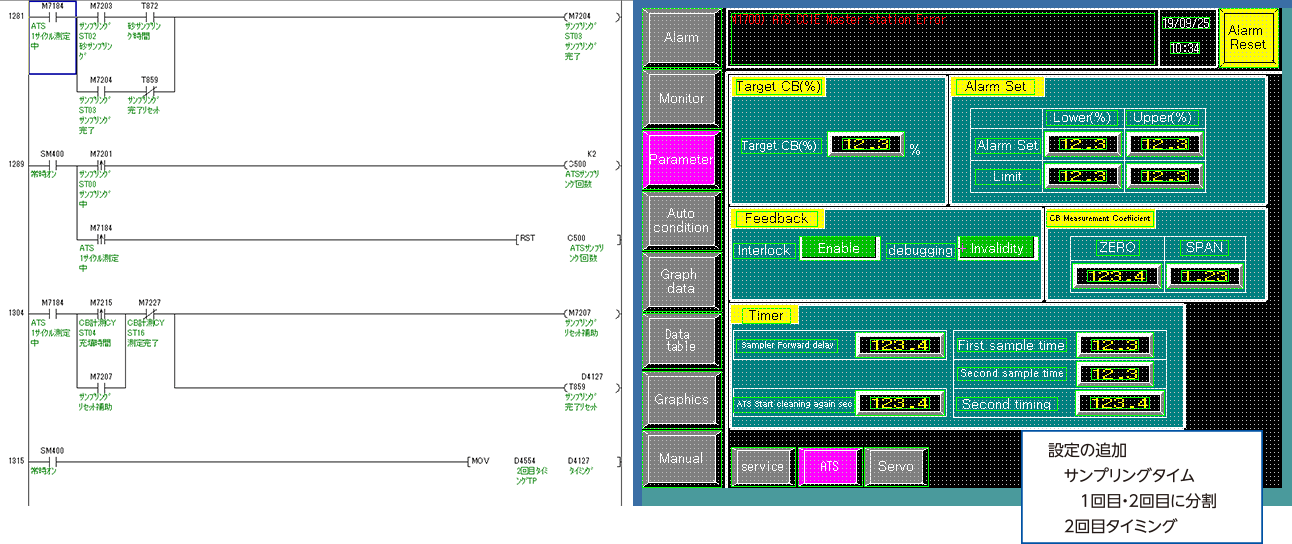

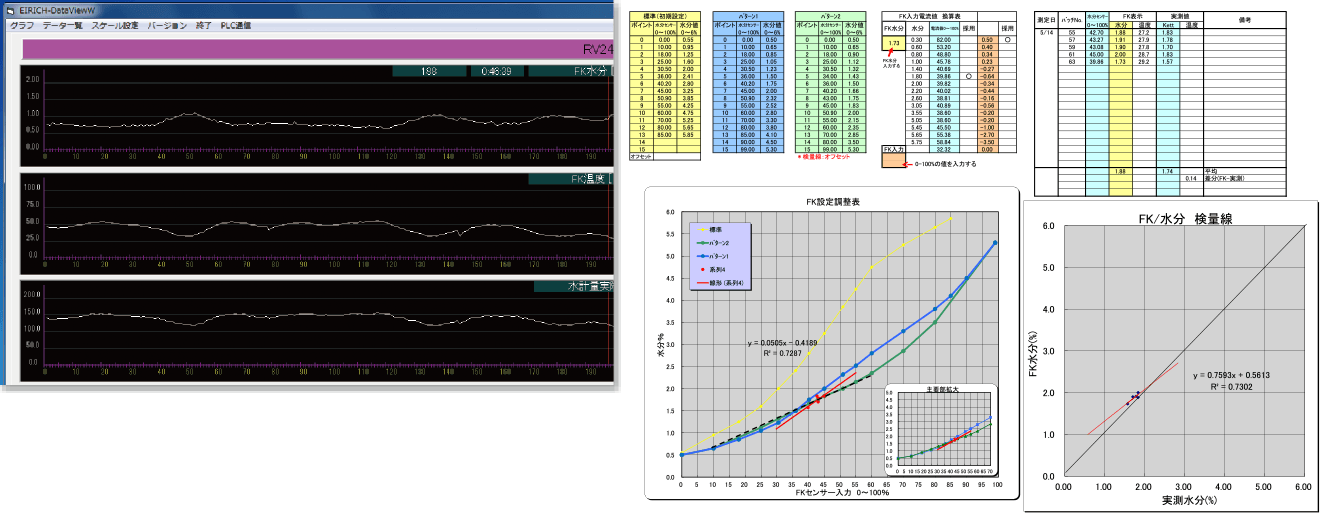

Solution

- Software change, touch panel screen change

- Analysis of collected data and recommendation of optimal parameters

- Calibration of various sensors

Raw Material Processing Examples

We proposes more ideal material processing by combining the know-how accumulated by Eirich Group around the world with our own technological development efforts.