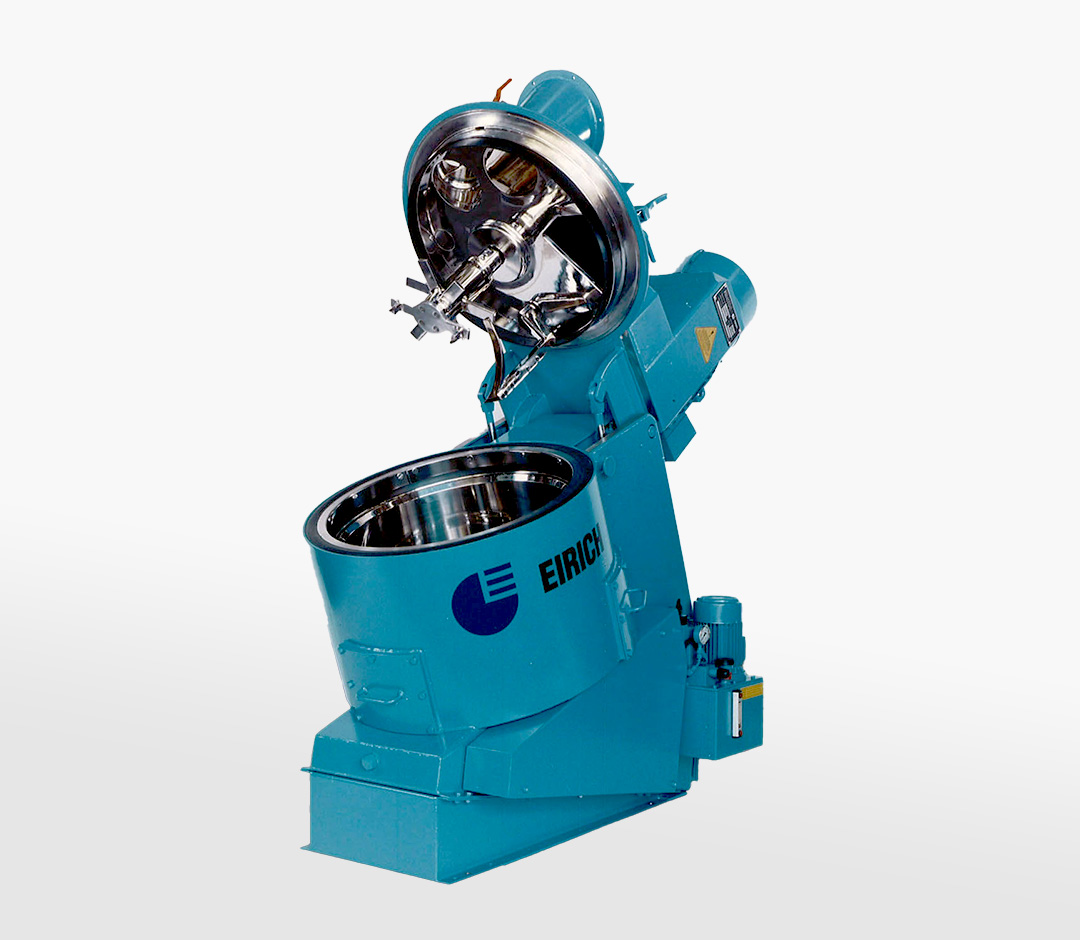

EIRICH Intensive Mixer

- Processes

- Mixing, kneading, granulating/pelletizing, dispersing, reacting, cooling/drying, grinding, attrition, disintegrating, defibrating, plasticizing, slurrying, coating

The unique mixing principle enables a "one-pot process" in which all of the above processes are carried out in a single mixing pan (mixing vessel). You can reduce the installation area, reduce initial costs, omit the transfer process between facilities, and simplify operations.

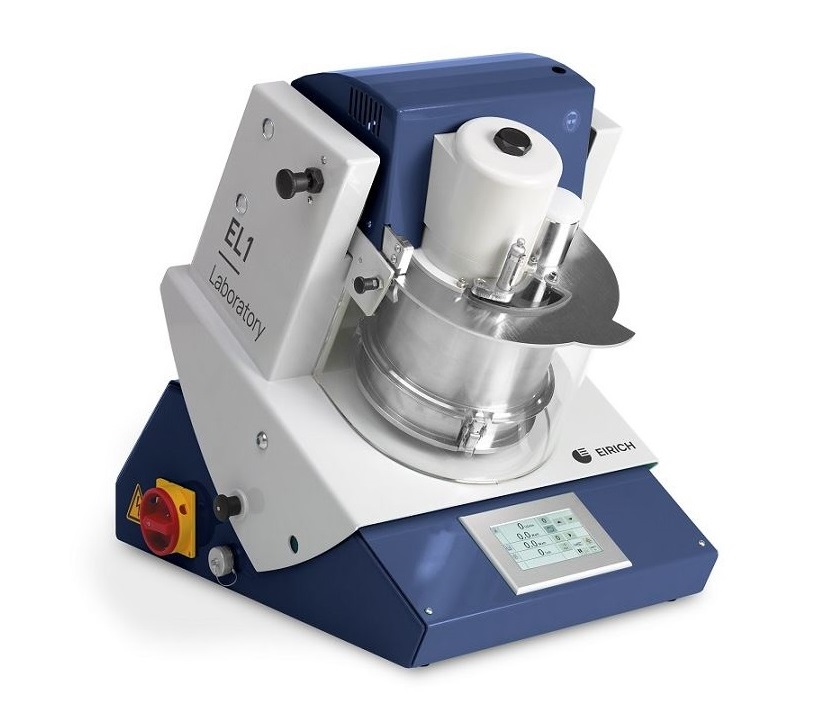

EL1

EL1-INOX

EL5 Eco (R02)

R02VAC

EL5 Profi Plus

R05T

R08W

RV12W

| Type | Capacity (L) | Capacity (kg) |

|---|---|---|

| EL1/EL1-INOX | 1 | 1.6 |

| EL5 Eco (R02) | 3~5 | 8 |

| R02VAC | 3~5 | 8 |

| EL5 Profi Plus | 3~5 | 8 |

| R05T | 40 | 65 |

| R08W | 75 | 120 |

| RV12W | 400 | 650 |

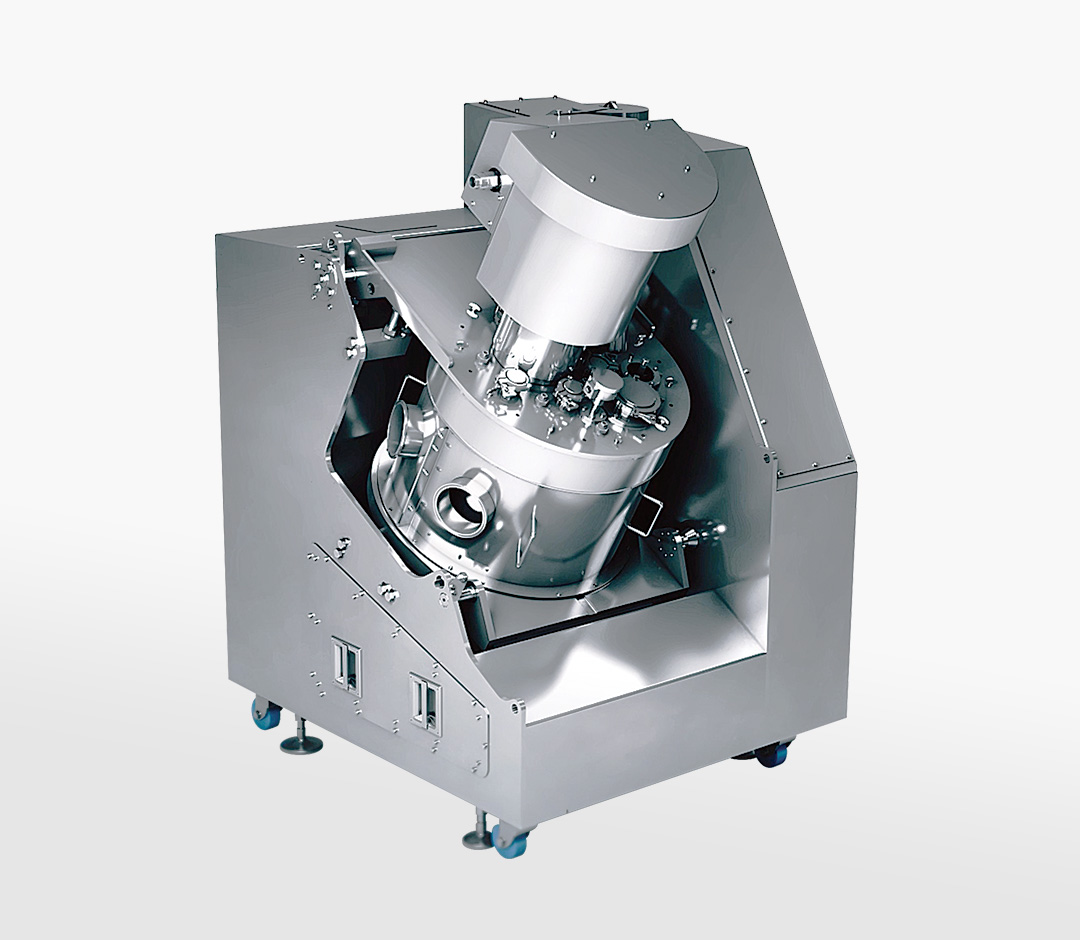

EIRICH CleanLine

- Purposes

- Mixing, kneading, granulating/pelletizing, reacting, drying/cooling, attrition, disintegrating, defibrating, plasticizing, slurrying, coating

Like EIRICH Intensive Mixer, CleanLine has a “one-pot process” function that enables multiple purposes in a single mixing pan (mixing vessel). In addition, CleanLine has the following advantages: cooling and heating function of the mixing pan, and waterproof and cleanable flat structure.

C5

C40

| Type | Capacity (L) | Capacity (kg) |

|---|---|---|

| C5 | 5 | 8 |

| C40 | 40 | 65 |

OptimaBlend™

- Processes

- Mixing, dispersing

OptimaBlend™ is a blender that provides homogenous mixes independent of large range of particle size, shape, or density of the ingredients. The unique shape of the paddle makes mixing fast and smooth without changing the shape of the material.

FPB-5

| Type | Capacity (L) |

|---|---|

| FPB-5 | 142 |

EIRICH TowerMill®

- Purposes

- Wet grinding

TowerMill grinds various raw materials such as limestone and iron ore from about 10 mm to several microns.

NE-008

KM-5

| Type | Circulation Capacity (L) | Grinding Ball Diameter | Material Size |

|---|---|---|---|

| NE-008 | 8 | Less than 6mm | Less than 3mm |

| KM-5 | 120 | Less than 20mm | Less than 10mm |

Technical Center is equipped with a variety of measuring instruments. You can evaluate processed materials in real time while testing.

Raw material measurement

- Measurement of physical properties such as particle size distribution, true density, bulk density, angle of repose, angle of rapture, and compactability

- Moisture content (moisture measurement)

- Surface condition observation (SEM, digital microscope)

Measurement for observation during raw material processing

- Equipment load monitoring and data logging

- Product temperature and concentration measurement by sampling

- Compactability (CB) measurements (sand rammers)

- Measuring withstand pressure and shear force (universal casting sand strength tester)

- Air permeability measurement (air permeability tester)

Result measurement after raw material processing

- Surface condition observation (SEM, digital microscope)

- Compactability (CB) measurements (sand rammers)

- Measuring withstand pressure and shear force (universal casting sand strength tester)

- Air permeability measurement (air permeability tester)

- Wet and dry sieves

- Dryer (constant temperature chamber with air flow circulation, fluid-bed dryer)

Raw Material Processing Examples

We proposes more ideal material processing by combining the know-how accumulated by Eirich Group around the world with our own technological development efforts.