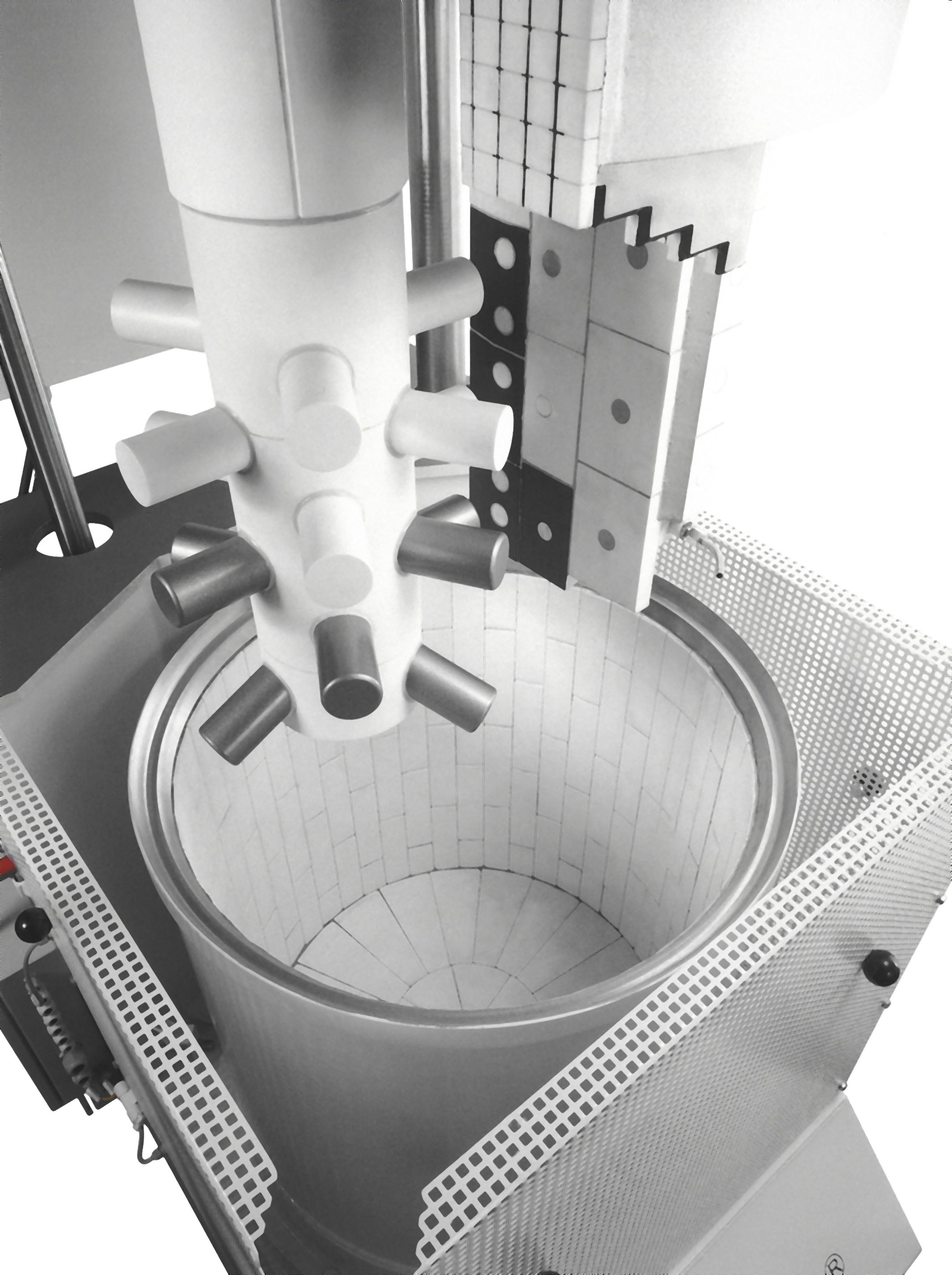

MaxxMill® is an agitated media mill for dry and wet fine grinding developed based on the unique mixing principles of Eirich Intensive Mixer.

Efficient agitation of the grinding media allows for “metal-contamination-less” specifications in the fine grinding of ceramics, glass materials, and other materials.

Major processes

- Flexible material selection to match the product

- Easy cleaning and maintenance

- Small space requirement, low noise and vibration

- Low specific energy consumption

- Applicable to dry and wet fine grinding

Materials are fed through a hollow flow deflector into the bottom of the rotating grinding chamber, where materials are ground by grinding media (3-10 mm) that is vigorously agitated by the eccentric agitator. The ground particles are collected from the product outlet.

- Silica

- Feldspar

- Glaze

- Porcelain raw materials

- Glass raw materials

- Aluminum oxide

- Ferrite filler

- Pigments

- Bentonite

- Ores

- Gypsum

- Special cement

- Calcium carbonate etc.

MaxxMill®

| MaxxMill® MM3 | MaxxMill® MM5 | ||

|---|---|---|---|

| Processing Volume | (ton/hr) | ~2.5 | ~10 |

| Grinding Vessel Capacity | (liter) | 190 | 800 |

| Power | (kW) | 25~50 | 120~200 |

| Grinding Media Diameter | (mm) | 3~10 | |

| Grinding Material | (mm) | 2mm or less | |

| Product | (D97) | Approx. 5μm | |

| Approximate Size | H/W/D | 260 x900 x1700 | 3500 x2000 x3100 |

| Approximate Weight | (ton) Quantity | 3.5 | 11.5 |

* The above processing volume and product particle size are for reference only. It will vary depending on the material to be ground and the required particle size.

** Specifications are subject to change depending on the type of material and grinding conditions.

Industrial Chemicals

Building Materials

Environmental Protection

Ceramics

Glass

Chemical Products

Paints/Inks/Coatings

Steel/Nonferrous Metals

Raw Material Processing Examples

We proposes more ideal material processing by combining the know-how accumulated by Eirich Group around the world with our own technological development efforts.