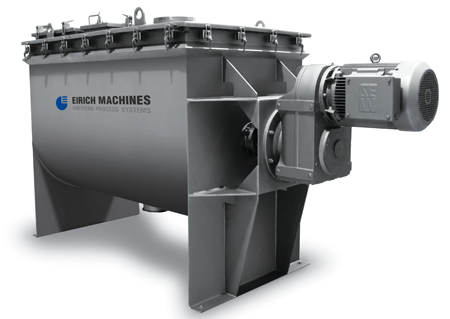

OptimaBlend™, developed by Eirich Machines (USA), a member of the Eirich Group, is a blender that provides homogenous mixes independent of large range of particle size, shape, or density of the ingredients. The unique shape of the paddle makes mixing fast and smooth, and it can handle small to large batches of material without changing the shape of the material.

Major processes

- High particle movement

- Homogeneous mixes independent of large range of particle size, shape, or density

- Extremely gentle with fragile ingredients

- Short processing time

- Increased production capacity

- Wide variety of material feed and discharge mechanisms

The paddle rotor inside the mixing vessel creates turbulence in the material. Compared to a ribbon blender of the same size, the tip speed of the rotating tool is more than twice as fast, and there is less dead space in the mixing vessel, enabling efficient mixing in a shorter time.

OptimaBlend™

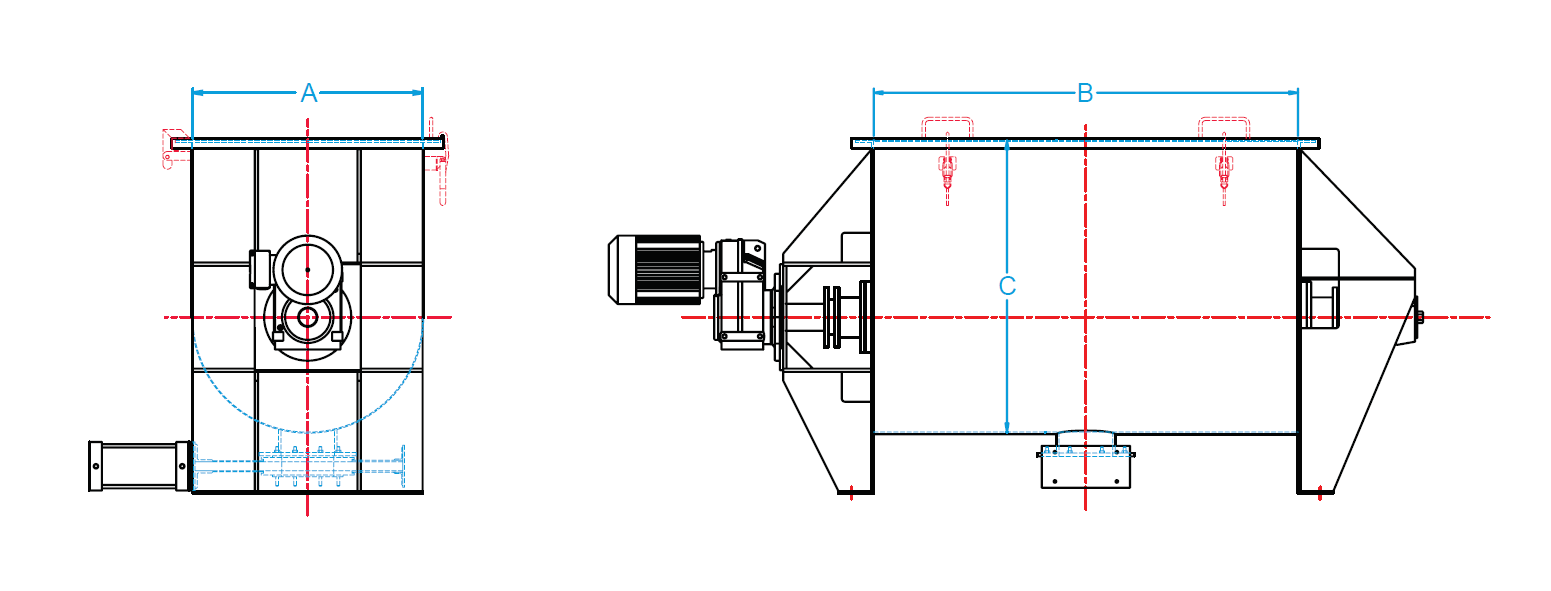

| Type | Volume L(Ft3) | kW(HP) * Varies depending on application |

Dimension mm (inches) | ||

|---|---|---|---|---|---|

| A | B | C | |||

| FPB-1.5 | 42.5(1.5) | 2.2(3) | 355(14) | 609(24) | 533(21) |

| FPB-5 | 142(5) | 2.2(3) | 533(21) | 914(36) | 711(28) |

| FPB-10 | 283(10) | 3.7(5) | 660(26) | 1,219(48) | 838(33) |

| FPB-20 | 566(20) | 5.5(7.5) | 813(32) | 1,372(54) | 990(39) |

| FPB-30 | 849(30) | 11(15) | 940(37) | 1,676(66) | 1,118(44) |

| FPB-40 | 1,133(40) | 15(20) | 1,067(42) | 1,829(72) | 1,244(49) |

| FPB-50 | 1,416(50) | 22(30) | 1,143(45) | 1,981(78) | 1,320(52) |

| FPB-75 | 2,123(75) | 30(40) | 1,270(50) | 2,286(90) | 1,448(57) |

| FPB-100 | 2,831(100) | 37(50) | 1,371(54) | 2,438(96) | 1,549(61) |

| FPB-125 | 3,539(125) | 37(50) | 1,524(60) | 2,743(108) | 1,702(67) |

| FPB-150 | 4,247(150) | 45(60) | 1,676(66) | 2,743(108) | 1,854(73) |

| FPB-175 | 4,955(175) | 45(60) | 1,676(66) | 3,048(120) | 1,854(73) |

| FPB-200 | 5,663(200) | 55(75) | 1,829(72) | 3,048(120) | 2,007(79) |

| FPB-250 | 7,078(250) | 55(75) | 1,829(72) | 3,353(132) | 2,007(79) |

| FPB-300 | 8,494(300) | 75(100) | 2,032(80) | 3,658(144) | 2,210(87) |

* Values in L, kW, and mm are approximate converted values.

Food Products

Cosmetics

Chemical Products

Raw Material Processing Examples

We proposes more ideal material processing by combining the know-how accumulated by Eirich Group around the world with our own technological development efforts.