Hygienic design mixer, conformity to GMP (possible as option)

EIRICH CleanLine, made in Japan, has been developed to meet many requests from customers who require GMP for pharmaceuticals, health foods, and other products.

A wide lineup of small to large machines is available, allowing gradual scale-up from the development stage to production.

In addition, the combination of a unique mechanism of the rotating mixing pan and EIRICH Smart Discharger, a suction-type product discharger, has realized safe and hygienic “automatic product discharge” without the need for operator intervention.

Major processes

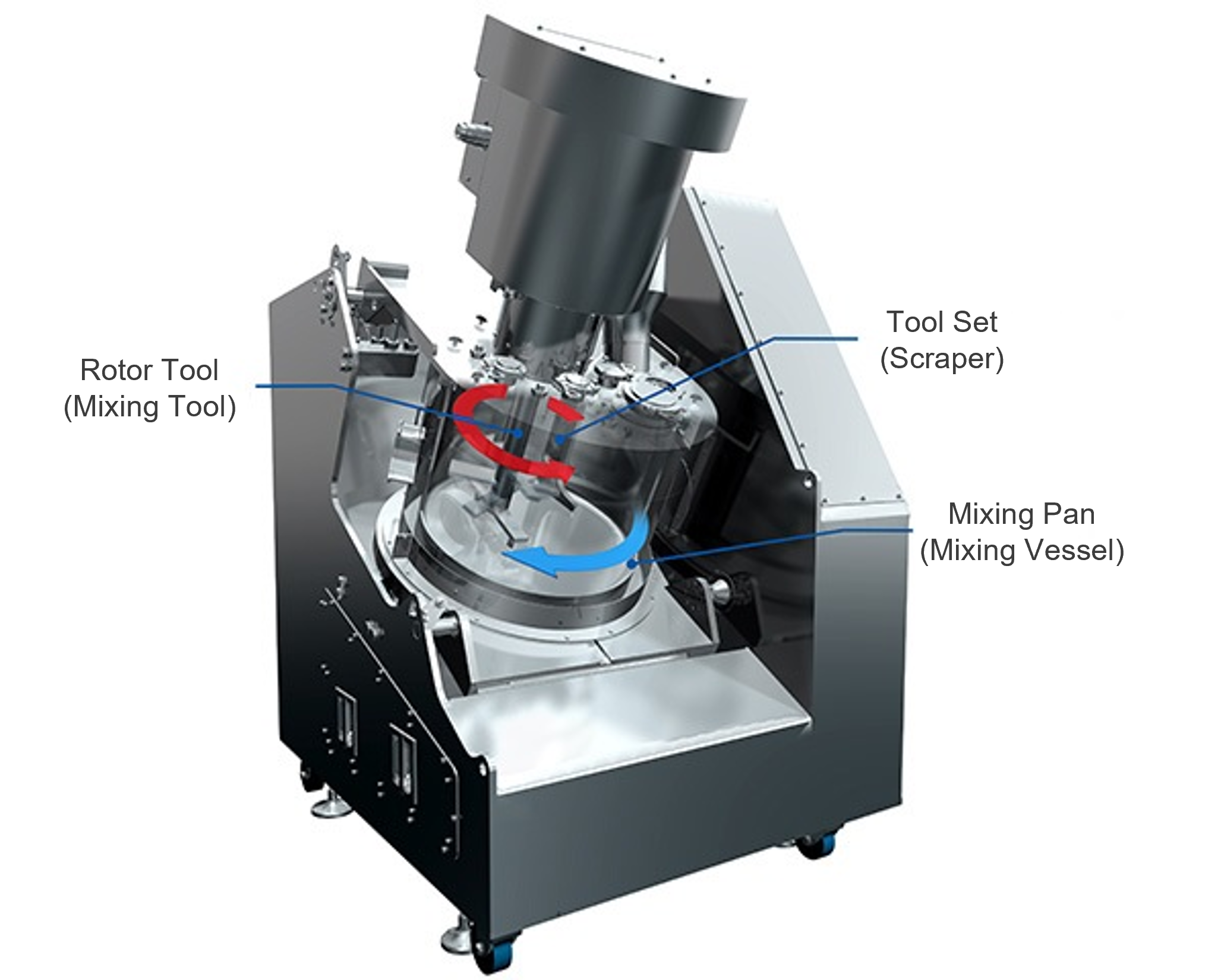

- Widely-adjustable rotor tool (mixing tool) speed (max: 30 m/s)

- Waterproof and cleanable flat structure

- Reduction of build-up of material and residue thanks to reverse jet nozzles and tool set (scraper)

- Cooling and heating of the mixing pan (mixing vessel) possible

- Use of explosion-proof motor and equipment, with air purge function inside the machine frame

- Various raw material processing such as mixing, dispersing, kneading, granulating, and coating etc. in a single machine

- Conformity to GMP (possible as option)

- Enables agitative granulation for pharmaceutical raw materials

- Like EIRICH Intensive Mixer, it is composed of a mixing pan (mixing vessel), a rotor tool (mixing tool), and tool set (scraper).

- It has all the features and advantages of the unique EIRICH mixing principle.

EIRICH CleanLine

| Type | Max. Capacity(L) | Max. Capacity(kg) | Batch-type | Country of Origin | Conform to GMP | ESD* |

|---|---|---|---|---|---|---|

| C5 | 5 | 8 | ● | Japan | Option | - |

| C40 | 40 | 65 | ● | Japan | Option | Option |

| C400 | 400 | 650 | ● | Japan | Option | Option |

* ESD: EIRICH Smart Discharger (suction-type product discharge device)

* Please contact us for options and other specifications.

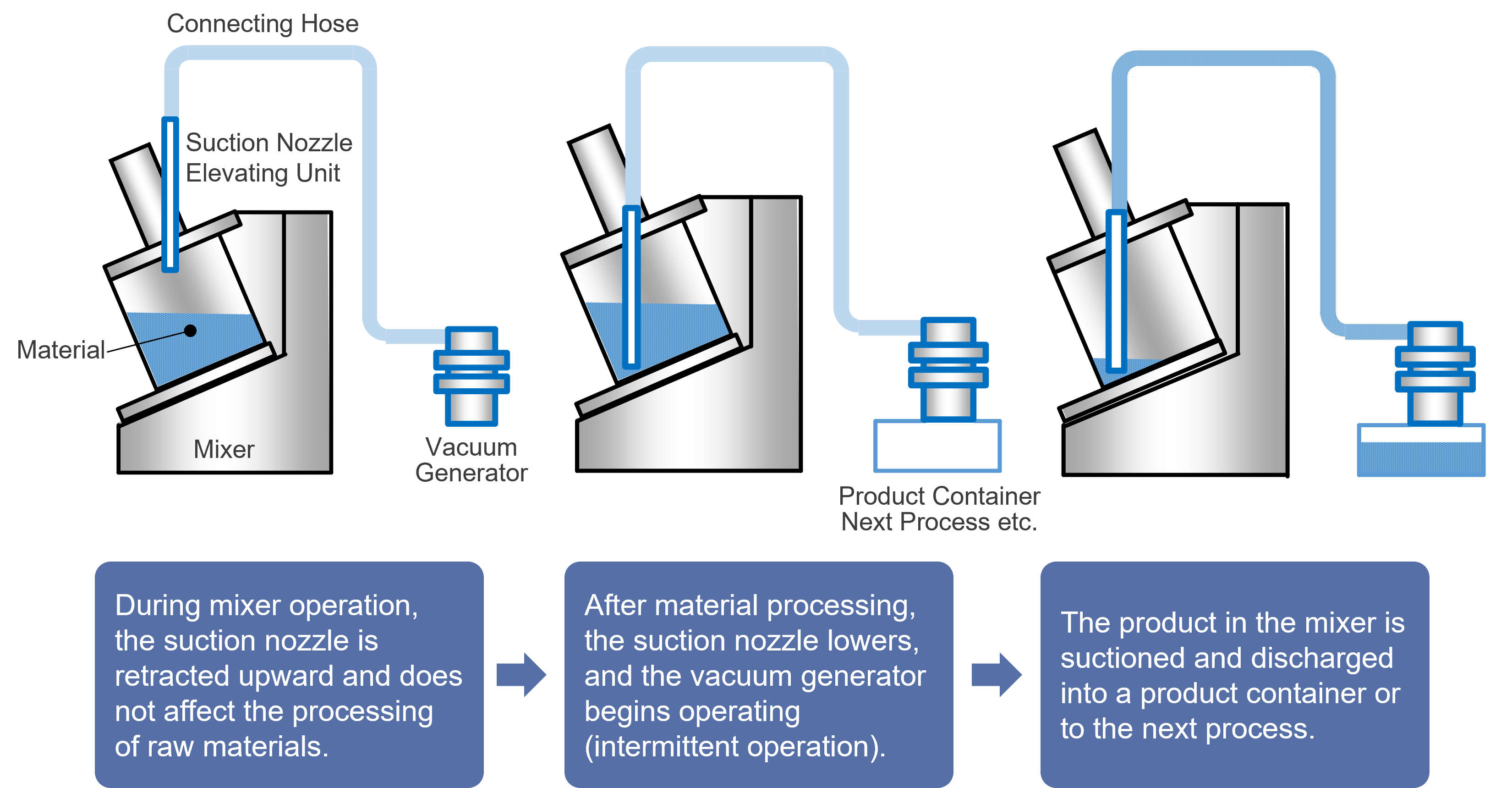

EIRICH Smart Discharger (ESD), Suction-type Product Discharge Device

This is a suction-type product discharge device that uses a combination of a nozzle attached to the top of the mixing pan and a vacuum generator.

The pneumatic discharge mechanism allows discharge without damaging products and requires no operator intervention until product discharge is complete. The product can be discharged to any destination, such as to a product storage container or to the next process.

Advantages

- Discharge without damaging products, thanks to a pneumatic discharge mechanism

- Complete material discharge because the rotation of the mixing pan promotes product discharge

- Significant reduction of dust emissions during discharge, because of no need to open and close the mixer until discharge is complete

- Work in a closed environment from the start of operation to the completion of discharge, possible

- Reduction of transportation process to the next process, labor saving, and shortening of the process, possible

Key milestones in the development of a wide variety of industries and applications are firmly linked to Eirich mixing technology. More

Pharmaceuticals

Health Foods

Dental Materials

Cosmetics

Industrial Chemicals

Technical Ceramics

(pdf, 1.0 MB)

CleanLine Series

(pdf, 1.3 MB)

CleanLine C5

Raw Material Processing Examples

We proposes more ideal material processing by combining the know-how accumulated by Eirich Group around the world with our own technological development efforts.